Screw Compressors and the Challenges of Hydrogen Compression

Welcome back to our exploration of the intricate world of hydrogen compression, where each rotation of a compressor holds the key to unlocking the potential of hydrogen in diverse applications. In this segment, we dive deeper into screw compressors and some of the challenges associated with their use for hydrogen compression. If you missed the first blog in the series titled “An Introduction to Hydrogen Compression”, make sure to read it here.

Compressors for Hydrogen Application

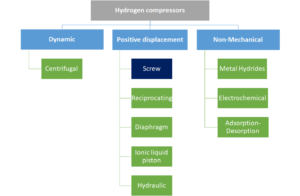

Various compression technologies are used for hydrogen applications, including positive displacement, dynamic, and non-mechanical compressors. The choice depends on factors like discharge pressure, capacity, intermittent operation, and hydrogen purity requirements. Considerations such as cost, efficiency, and technology maturity also play a role. In this blog, we will be focusing on screw compressors.

The Evolutionary Journey of Screw Compressors

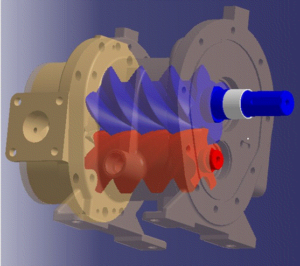

Originating in the 1930s, screw compressors have secured their place in applications demanding substantial capacities within confined spaces and constrained discharge pressures. Employing interlocked male and female screws, these compressors create a compression chamber, enabling pressurization through continuous rotation. Balancing between the capacities of reciprocating and dynamic compressors, screw compressors regulate capacity through variable speed, sliding valves, or recirculation.

Screw compressors can be categorized into oil-free and oil-flooded types. Both find application in single or multi-stage configurations in hydrogen applications, albeit in distinct operating ranges determined by their design constraints, such as rotor circumferential speed, differential pressure, and delivery volumes.

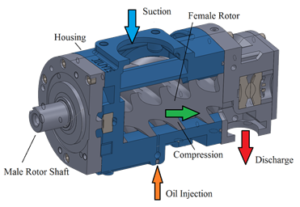

Oil-Flooded Screw Compressors

Oil-flooded screw compressors have oil injected into the compressor to cool the gas, seal the gaps and lubricate rotors and bearings. This results in a compact design with smaller bearing distances. The main driving rotor directly engages with the rotating gate rotor, requiring a continuous oil lubrication film. These compressors handle high differential pressures and bearing loads, operating at lower circumferential speeds and achieving relatively high volume rates. In open systems it is essential to compress wet gas above the dew point to prevent water condensation into the oil. Pre-drying is advisable to enhance operating costs and extend the oil’s service life. Oil injected screw compressors may include an oil-lubricated slide valve, which regulates volume flow and internal pressure at constant speeds, serving as an internal bypass and a start-up unloader.

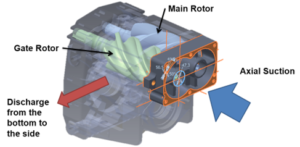

Oil-Free Screw Compressors

Oil-free (dry) screw compressors have a compression chamber completely free from oil which requires appropriate seals between the working chamber and bearings. The gate rotor is synchronized through a gear pair with the driving main rotor without direct contact. Differential pressures are limited due to a steep rise of the gas discharge temperature which is a function of the heat capacity ratio of hydrogen. Realistic pressure ratios in a single-stage hydrogen compressor are up to 4. For achieving higher pressure ratios, expensive multistage compressors are required. Adding that to expensive sealing requirements, dry screw compressors are an order of magnitude more expensive than their oil-injected equivalents. However, these compressors operate at maximum circumferential speed and volumes and there are no requirements to compress wet gas above the dew point.

Oil-free screw compressors with water injection achieve oil-free compression using injected water for both cooling and gap sealing. The rotors are usually synchronized through a gear pair. With some advanced rotor profiling techniques and rotor materials, it is possible that compressors could also be directly driven without a need for synchronizing gears. However, such solutions are challenging due to the possibility that the oil used for the lubrication of bearings could be mixed with hydrogen and water. However, these compressors can operate at higher speeds and volumes than oil-injected compressors and with higher pressures than dry screw compressors. There is also no need to compress wet gas above the dew point. Significant efforts have been invested in both academia and industry to develop affordable and reliable technologies for water-injected screw compressors (Read more about this here, Project SECRET).

Challenges in Hydrogen Applications

In essence, there are two critical considerations that industry experts and academics face when compressing hydrogen. These are hydrogen purity and capacity/pressure requirements.

Hydrogen Purity

High-purity hydrogen is vital for industries like electronics and pharmaceuticals, as well as fuel cell technologies, where trace impurities can cause significant issues. Non-lubricated compressors are preferred for applications requiring stringent purity levels, eliminating the risk of introducing contaminants. Maintaining high hydrogen purity is essential for the efficiency of end-user processes and contributes to the longevity and performance of downstream components such as fuel cells, capacity and pressure

Capacity and Pressure Requirements

The selection of a compressor for a specific duty depends on the required volume flow and pressure. Hydrogen is the lightest of all gasses. Its molecules are very small and tend to leak more easily than other gasses. Due to the gaps between rotating and stationary elements, screw compressors can be used only for limited volume and pressure demands. Screw compressors are typically used for applications up to 40,000 Nm3/h and pressure up to 30 but the range is constantly expanding due to new research and technologies.

Screw Compressors Solving Problems

As we better understand the different types of screw compressor technologies available and identify some of the challenges related to hydrogen purity, capacity, and pressure, we can begin to see how screw compressors can solve these problems and offer an ideal solution in low-pressure hydrogen applications. In our next blog, we will discuss this in more detail and also look at how SCORG can help maximize the potential of your screw compressors to meet hydrogen application needs.

The Future is Hydrogen Compression Blog Series

In this 3 part blog series titled The Future is Hydrogen we explore the growing demand for an eco-friendly hydrogen economy. Hydrogen is becoming a crucial energy carrier with many countries adopting strategies to cut carbon emissions and link different sectors. The hydrogen compressor sector is going to play a pivotal role in this journey so join us as we explore the what, why, and hows of Hydrogen compression.

Blog 1: An Introduction to Hydrogen Compression

To stay up to date with PDM Analysis, follow us on LinkedIn here and Twitter here.