What is the input format for rotor profiles?

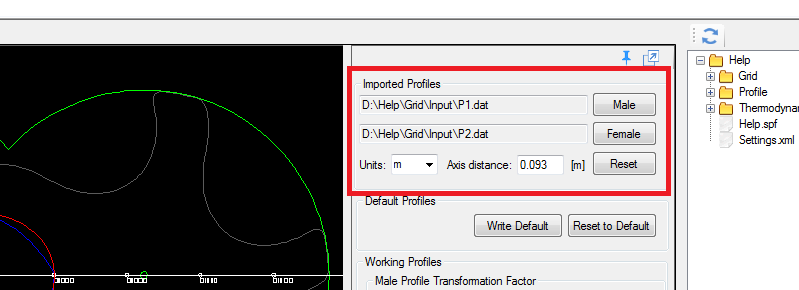

Rotor profiles are imported through User profile tab in form of data files.

Two data files need to be imported: Male profile and Female profile.

Data files may be from software that generates them, may be measured using CMM machine or from CAD model. The accuracy of the performance prediction will depend on the accuracy of the profile files and it is known that CAD generated files may introduce in the representation of the profile.

For more information please see online documentation

Can the User Profile be imported directly from CAD?

No, the user needs to extract data points from CAD system first and then to import data files.

The new SCORGTM 3D viewer is coming soon and will include this function to import profile form CAD system.

For users of Solidworks a macro is available that can help in extracting profile points from CAD curves and exporting into MS Excel

What is the difference between User Profile and Generated Profile?

User Profile: These are profiles defined by point coordinates and imported into SCORGTM

Generated Profile: SCORGTM has functionality to generate conjugate rotor profile pairs internally for specified geometrical parameters. This tool is available for special license and further details can be made available when you contact us

How to set the interlobe, radial and end leakage gap size for thermodynamic chamber model?

Interlobe gap size to be used for thermodynamic calculations is set in the Profile setup: GAPI

Profile –> Profile Setup

Radial and End Leakage gap size for thermodynamic calculations is set in the Machine configuration setup

Geometry –> Machine Configurations

Are real gas properties available for thermodynamic chamber model?

Not in release v5.1 but we plan to implement real gas in our future release to be used with thermodynamic chamber model

How to set the interlobe, radial and end leakage gap size for CFD rotor grid?

Interlobe gap size to be used for Grid generation is dependent on the imported rotor profile and is additionally set in the Profile setup as an incremental quantity: GAPI

Profile –> Profile Setup

Radial Leakage gap size for Grid generation is set in the Machine configuration setup

Geometry –> Machine Configurations

End Leakage gap size setting is not used by Grid generation

In what format is grid generated by SCORG available?

SCORGTM Grid Generator can provide mesh files in ANSYS CFX, ANSYS FLUENT, Simerics Pumplinx and STAR CCM+ native formats

Node positions for successive time steps are available as simple ASCII files with (x, y, z) patch

What is difference between theoretical suction and discharge ports and the actual?

Theoretical ports use theoretical built-in volume ratio to generate the port areas and the flow passages are simplified geometries so that thermodynamic chamber models can be applied or good quality hexahedral mesh can be generated for CFD analysis

For multiple female rotor grid generation what are the inputs required?

You only need to change the number of gate rotors in Geometry>>Machine Configurations >> N Gate

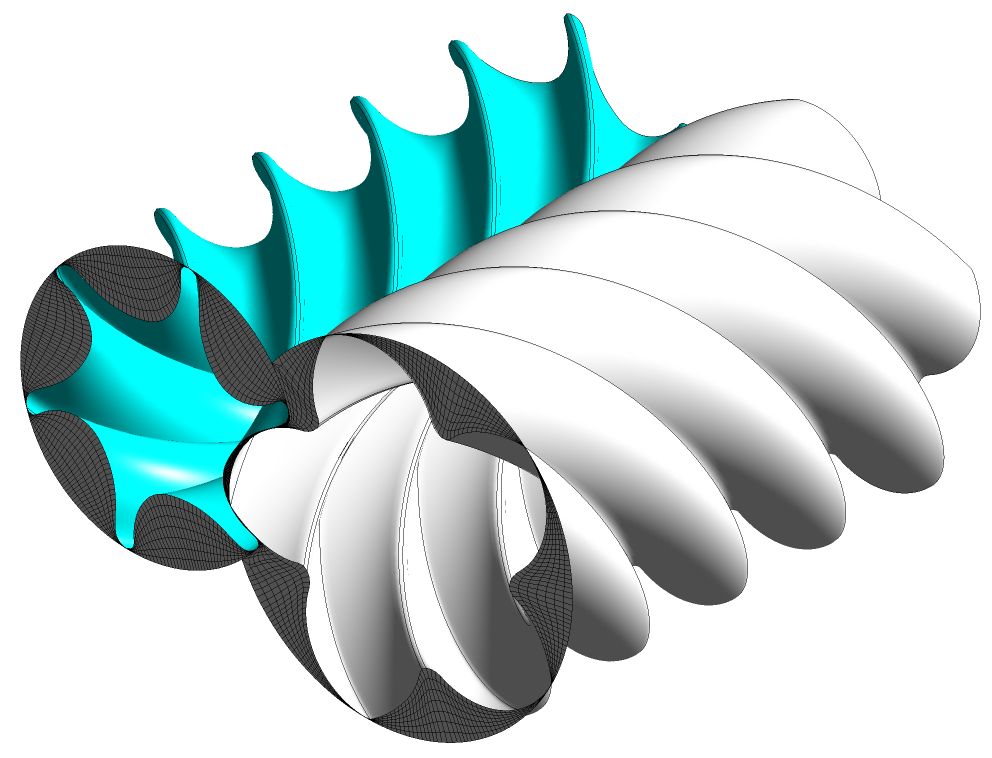

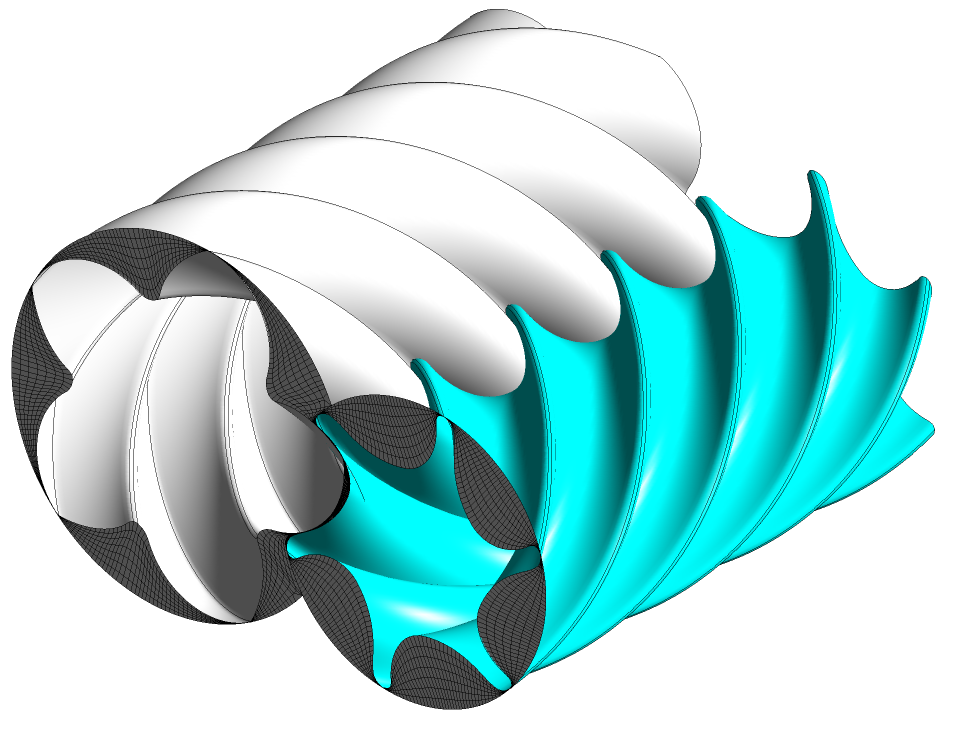

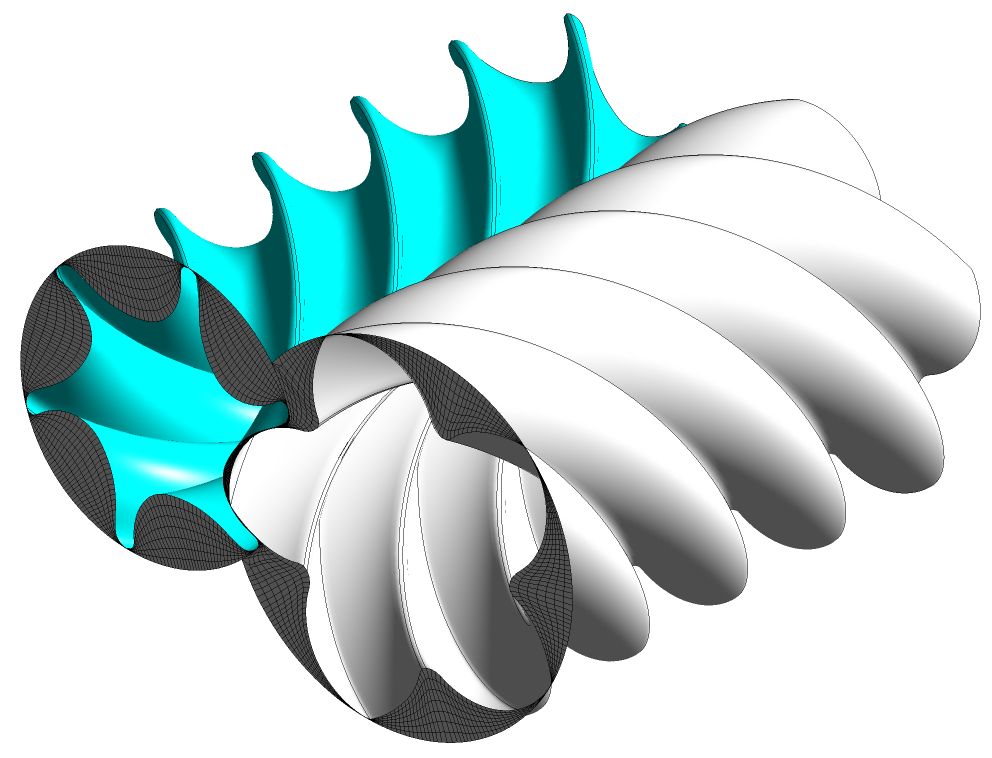

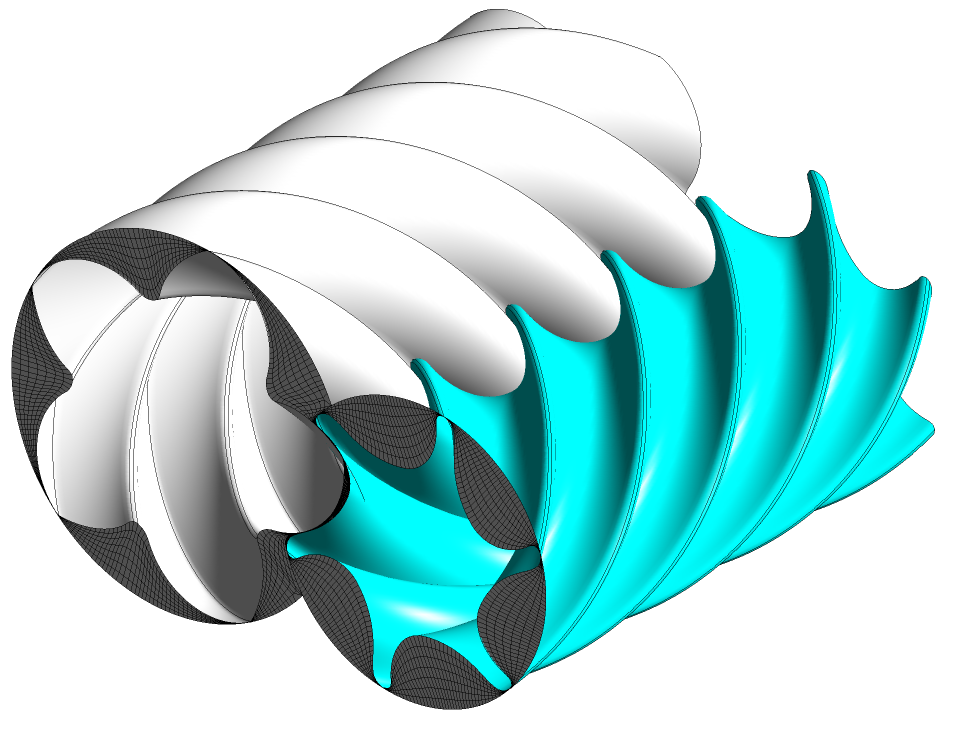

Below is an example of two gate rotors configuration

What is the typical node count required for a CFD simulation of twin screw compressor?

There are three different grid spacings that can be controlled using SCORGTM Grid Generator

Circumferential Divisions control the profile discretization.

Radial Divisions control the number of cells between the rotor and casing

Angular Divisions control the number of positions for which the mesh is generated and also the number of cross sections in the axial directions

Depending on the setting used for all these three parameters, a typical cell count in the rotor domain can go up to 2 million

Is it possible to place female rotor grid on the left or right side of the male rotor?

Yes this is possible. You can do this by changing the input in Geometry>> Rotor Configuration>>Gate Rotor Position

Below is an example of Left or right side gate rotor configuration

Is it possible to change the helix hand on the rotor grids?

Yes this is possible. You can do this by changing the input in Geometry>> Rotor Configuration>>Main Rotor Helix

Below is an example of Left or right hand Main rotor helix configuration

The Gate rotor will be automatically set