Prof. Ahmed Kovacevic presented the New Features in SCORG v2025 & Rotor Profiling as part of the first webinar in our SCORG v2025 Update Webinar Series. SCORG is our industry-leading grid generation and performance prediction software. It is a unique software for designing and analyzing positive displacement machines such as screw compressors, expanders, pumps, and motors.

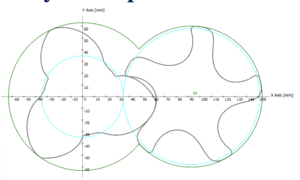

During this webinar, we learned that SCORG v2025 introduces powerful new features for the design and analysis of positive displacement machines, including twin screw, IGSM, Roots, vane compressors, expanders, pumps, motors, and Quimby vacuum pumps. The latest release offers advanced capabilities such as “N” rotor profile generation with clearance distribution, manufacturing tool generation, enhanced port and leakage area calculations for IGSM, and the ability to export 3D rotor and casing designs in multiple CAD formats.

SCORG v2025 also includes contact force and Hertzian stress calculations to optimize rotor durability. A new modular licensing structure — SCORG-Thermo, SCORG-CFD, and SCORG-Package — gives users flexibility based on their design and analysis needs. Updates improve oil injection modeling, bearing loss calculations, and thermodynamic analysis of vacuum pumps, while new manufacturing tools support profile milling, grinding, and hobbing.

SCORG v2025 continues to minimize design effort and maximize performance efficiency, reinforcing its position as the industry-leading tool for rotary positive displacement machines.

Release v2025 also features new templates and extended manuals and tutorials.

You can try the demo version for free, but please be aware that the newest version to purchase has more functionality than the demo variant.

Also, you can check all SCORG features in SCORG alto which is a cloud platform hosted in Microsoft Azure, enabling you to design and analyse screw machines using the software SCORG. Register and explore the abilities of our software by choosing the trial licence at a discounted price.