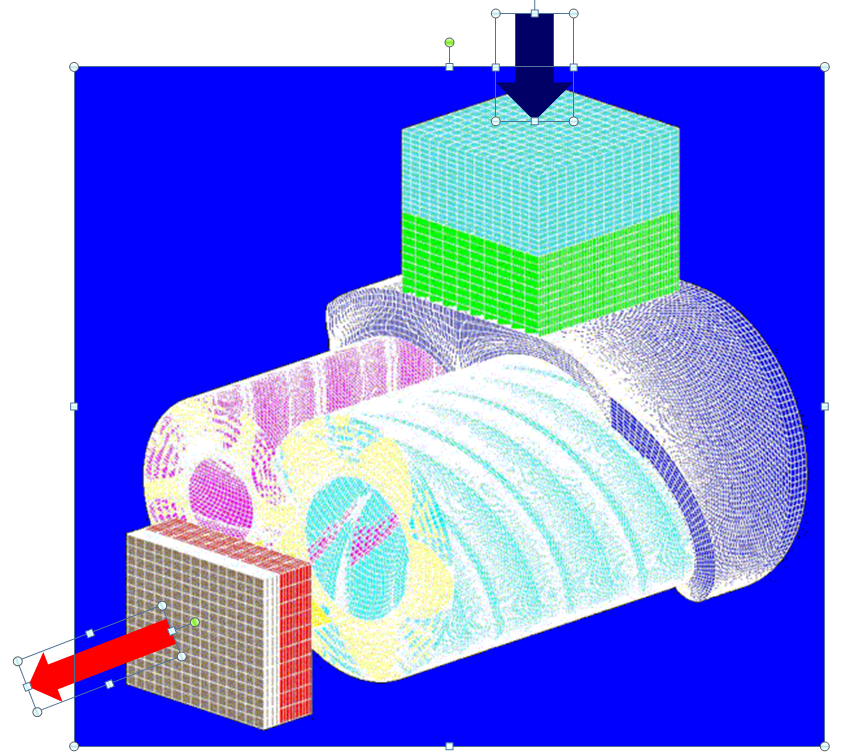

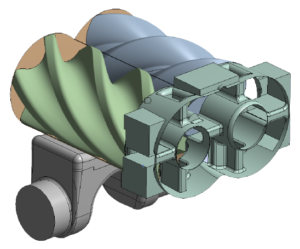

Optimisation of screw machines using CFD is becoming increasingly interesting topic for industrial R&D departments and academia. In such case it may not be required to invest time into developing a real 3D geometry of the inlet and outlet flow domains. Instead SCORG can be used to quickly generate these domains based on the ideal shape of the ports.

This approach is ideal for optimisation of rotors, liquid injection, internal built in volume ratio and other relevant parameters of screw machines. These domains shown in the figure can be parametrically modified and generated in a fraction of second to give fast and convenient solution and full ‘head start’ for CFD analysis.

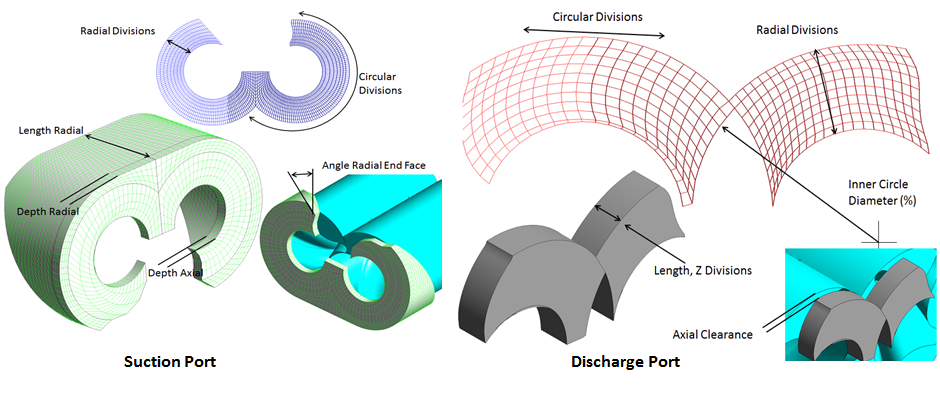

Low pressure port is the theoretical port connecting the rotor domain with the low pressure flow domain. In CFD model it is the place where the low pressure boundary conditions are applied. The position of that port dictates the timing of the connection of the working domain with the low pressure port. Thus it controls the capacity of the compressors or the built-in volume index of the motor. The low pressure ports can be generated in SCORG as Axial, combined Axial and Radial or only Radial.

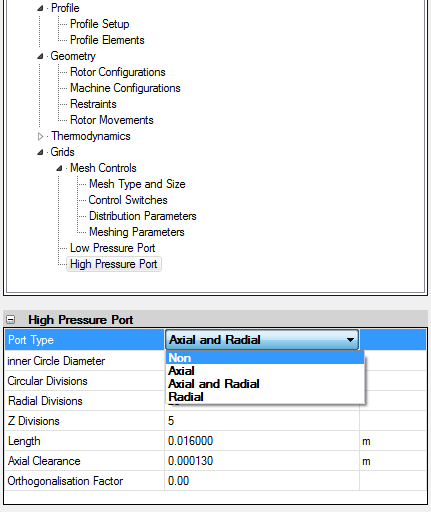

High pressure port generated in SCORG uses an ideal theoretical shape of the port profile and to connect the rotor domain with the high pressure flow domain in order to provide the high pressure boundary conditions and also control the timing of connection of the working domain to the high pressure flow domain. Thus it controls the built-in volume index in case of compressors which it turn defines the internal pressure increase in the machine.

For more details, please contact us.