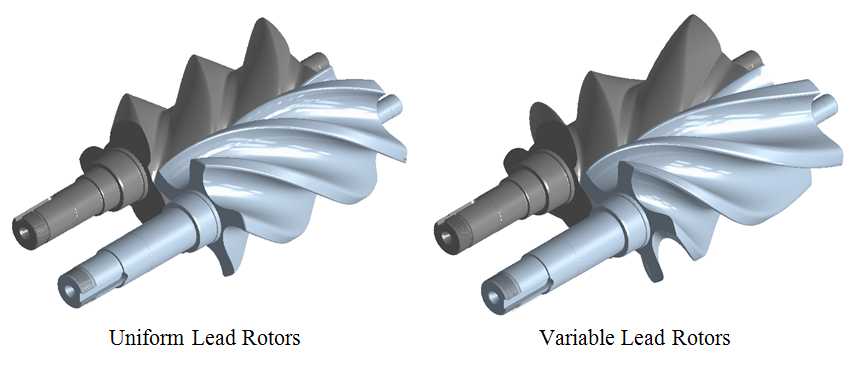

Twin-screw compressors for air compression and refrigeration have been used since the late 1950s. In all these years, the efforts of designers focused on optimising rotor profiles keeping the uniform rotor lead primarily due to manufacturing constraints.

However, it is well known that by varying the pitch and/or cross-section profile, the performance of a compressor could be improved. Variable lead rotors have been extensively used in vacuum pumps and more recently in multiphase pumps and have proven beneficial, although difficult to make.

With advancements in manufacturing and measurement technology and the new manufacturing methods, there are signs that screw machines with variable rotor profiles and variable rotor lead might be used more often in the future.

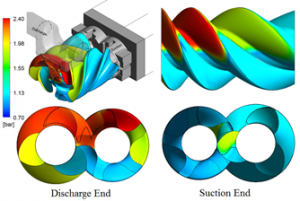

The prerequisite for the design of screw machines is the ability to design them, analyse their performance and optimise. SCORG® is today the best grid generator for screw machines that can produce numerical mesh for performance analysis of such machines.

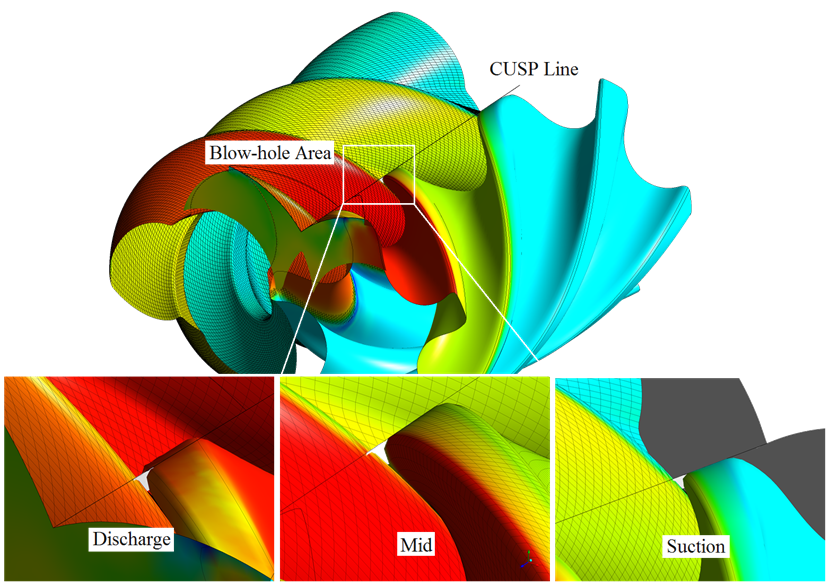

This example shows the use of SCORG® to generate numerical mesh for three different screw compressors:

- Constant rotor profile and constant rotor lead

- Constant rotor profile and variable rotor lead

- Variable rotor profile and constant rotor lead

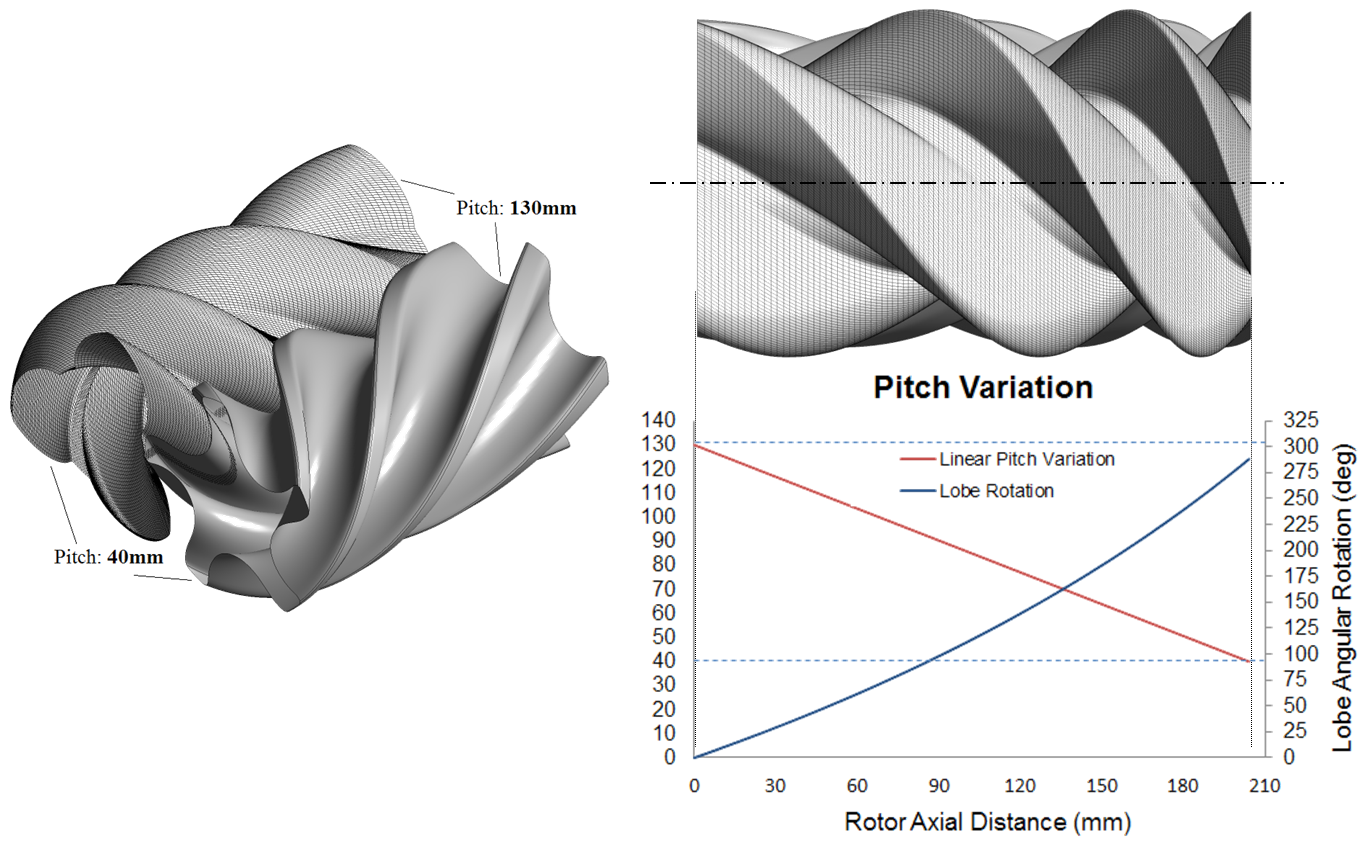

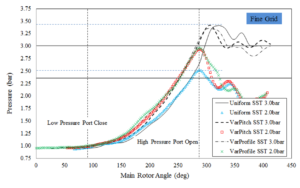

The main advantages of varying the lead on screw rotors are:

- Steeper internal pressure increases,

- Lower throttling losses due to increased discharge port area for a given pressure ratio,

- Decreased leakage losses due to the reduction in sealing line length towards the high compression zones.

More information about grid generation of variable geometry rotors could be found in the following publications:

- Rane, S., Kovacevic, A., Stosic, N. and Kethidi, M. (2013). CFD grid generation and analysis of screw compressor with variable geometry rotors. In: 8th International Conference on Compressors and their Systems. (pp. 601-612). Cambridge: Woodhead Publishing. ISBN 9781782421696

- Kovacevic, A., Stosic, N. and Kethidi, M. (2014). Deforming grid generation and CFD analysis of variable geometry screw compressors. Computers & Fluids, 99, pp. 124-141. doi: 10.1016/j.compfluid.2014.04.024

The capability of SCORG® to generate numerical grid for rotors with constant and variable lead as well as variable profile is demonstrated in the following video.

For more details, please contact us.