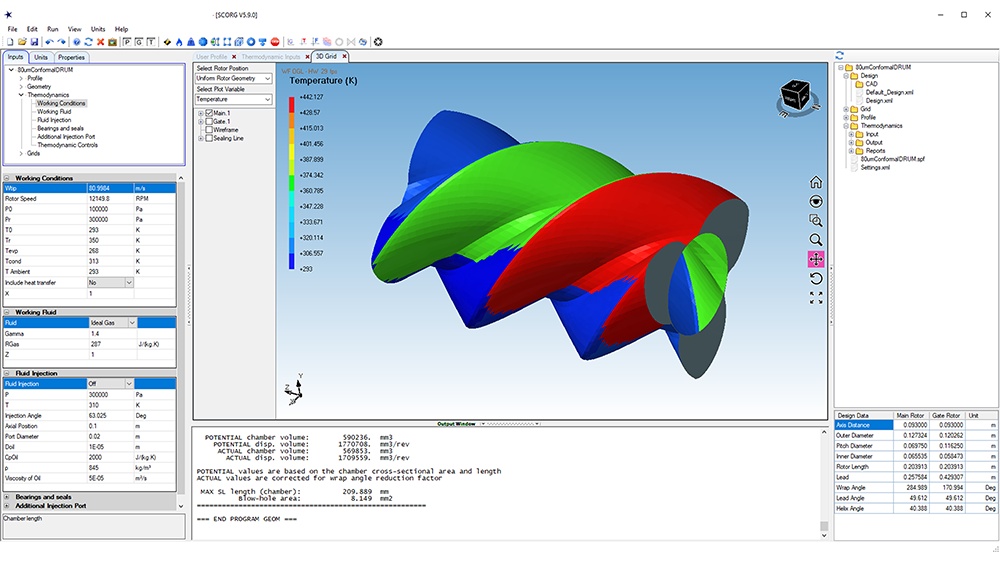

I am currently using SCORG® for my PhD on screw compressors for water as a refrigerant (R-718). The thermodynamic analysis of screw compressors is very challenging without proper tools. SCORG® has enabled me to do thermodynamic calculations of screw compressors in a matter of minutes. The setup of an operational model is very intuitive and is very well explained in the handbook and the detailed workshop videos. Thanks to SCORG® I can now focus on the actual challenges of screw compressors for R-718.

Thomas Mösch - Research Associate at Technische Universität Dresden

The makers of SCORG® really know screw machines inside and out, and their software provides top-notch insight into the thermodynamic behavior of these machines. They provide seamless integration with GT-SUITE software for multi-physics applications from pulsations, muffler design, bearings, and surrounding systems.

Jon Harrison - Staff Engineer at Gamma Technologies LLC

Here at OMIQ, we are specialised in vertical solutions for the virtual design of flow components. When a customer asked for the possibility of calculating a screw pump, we immediately thought about SCORG®. And we were right! The tool is friendly, quick to learn and provides all the relevant design information. It also generates high-quality meshes for our main CFD simulation tool, SimericsMP. Overall, a very productive and fruitful experience.

Federico Monterosso - Sales Director at OMIQ

SCORG® software is a valuable tool for anyone designing positive displacement screw compressors. Aside from the capability to generate complex CFD meshes, the lower-order thermodynamic model and related calculation tools provide everything needed for the basic design and performance evaluation of screw compressors. The team at PDM Analysis are very supportive and this is reflected by the new features and improvements introduced in every new release.

Dr David Buckney - Chief Engineer at Mayekawa UK Ltd.

We started using SCORG® in 2018 to improve the quality of fluid-dynamic design of screw compressors. Both thermo and mesher modules of SCORG® are great and powerful tools to help screw compressor designers and CFD analysts to improve the performances of the product, shortening design time and lowering costs for new product development and verification.

Luigi De Franco - Senior Mechanical Engineer, Head of fluid - dynamic design and CFD calculation office - R&D department at Termomeccanica

Early on Professor Kovacevic helped me learn and use SCORG®. It has become and valuable tool that is used at Trane for creating meshes for screw compressor CFD analysis. I have been using SCORG® for several years and it has helped Trane to create several different screw compressors designs. I have also presented several times at City University during the short course about how I have used your tool.

Scott M. Branch - Senior Compressor Design Engineer & the SME on screw/scroll compressor CFD analysis at Trane

For approximately one year, I have been using SCORG® multi-chamber thermodynamic modelling for design review and optimisation. Various projects have been modelled in this time, including oil-injected and oil-free machines. I can thoroughly recommend SCORG® as a design tool. My preferred method of working is to use Scorpath for rotor profile optimisation, tooling, and CAD modelling, then importing the profiles into SCORG® for performance evaluation and optimisation of the complete design. After verification, it is easy and cost-effective to apply virtual testing of a proposed design by simply changing the input conditions. I find it hard to imagine a screw compressor design without using SCORG® now.

Graham Stupple - Development Engineer at Jäcklin GmbH

SCORG® is a very professional software. We mainly use it to generate the grids for screw pumps.

Shuaihui Sun - Associate Professor at Xi’an University of Technology

As a part of our development process, we use SCORG® mainly for the discretisation of the fluid domain and obtaining pressure and temperature information which is a challenge because of the moving mesh conditions of screw rotors. Once this information is obtained, a Computational Fluid Dynamics (CFD) and structural analysis is carried out for design validation for customised solutions.

SCORG® has not only made contributions at the design level but also during the analysis of root cause finding for some of the failures. This was done by simulating actual operating conditions in SCORG® and finding out the localised thermally stressed regions within the compression chambers. After we were introduced to SCORG®, it has become a standard tool we use in our company to analyse the performance of our screw compressors.

Suraj Abdan - Manager, Design and Development, Air Compressor Division at Kirloskar Pneumatic Company Limited, Pune, India

SCORG® is groundbreaking software that solves complicated shape mesh issues and provides robust and stable CFD simulations. And above all, the technical support by experienced experts is very dependable for our research and development.

Yuichiro Abe - Engineer at MAYEKAWA MFG. CO., LTD.

Beijing Hikey Technology is a CAE industrial software provider founded in China over 20 years. We have cooperated with the energetic and productive PDM Analysis team for many years. Their tool, SCORG®, is a professional software for profile analysis and mesh generation of screw machines. We appreciate PDM’s professional support during past years!

Mandy Zhao - Business Operation Manager at Hi-Key Technology Corporation Ltd

My journey with SCORG® has been very interesting as I have been able to see how parameters affect the analysis both visually and graphically. It has helped me to grasp the complex working components of a screw compressor and is a useful tool for a graduate engineer, who is new to the Screw compressor industry.

Lihini Seneviratne - Graduate Engineer at Mayekawa UK

I have been using SCORG® for various projects at Carrier for a couple of years. We rely on SCORG® for creating screw rotor profiles, evaluating the performances of the profiles, and generating rotor meshes for CFD simulations. Surprisingly, SCORG® can generate 3D meshes with very accurate clearances. This has enabled us to capture the pressure pulsations in sound predictions very well. SCORG® has already played a very important role in our design procedure for screw compressors. As a long-time user, I love it!

Shawn Chen - Staff Engineer at Carrier